大样品的缺陷检测成像与分析

Park NX20拥有业界便捷的设计和自动界面,让你在使用时无需花费大量的时间和精力,也不用为此而时时不停的指导初学者。借助这一系列特点,您可以更加专注于解决更为重大的问题,并为客户提供及时且富有洞察力的失效分析报告。

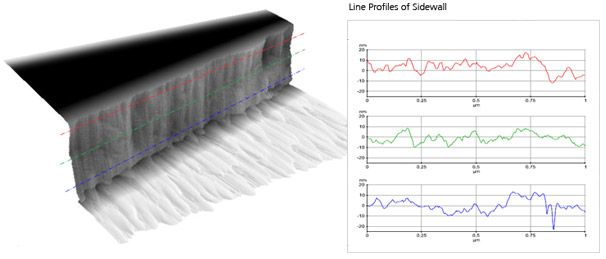

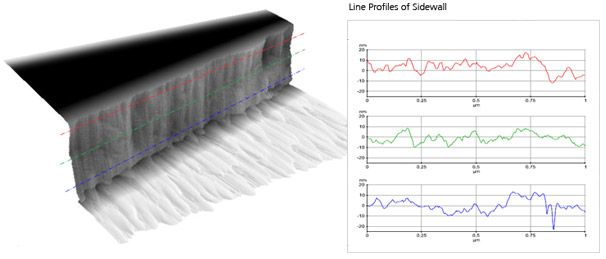

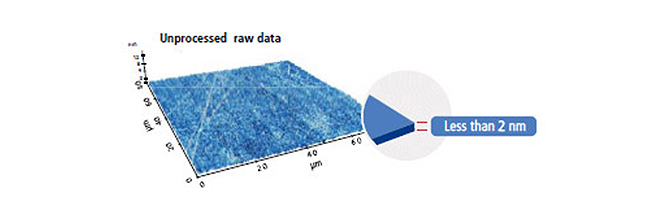

Park NX20可快速帮助客户找到产品失效的原因,并帮助客户制定出更多具有创意的解决方案。高精密度可为用户带来高分辨率数据,让用户能够更加专注于工作。与此同时,非接触扫描模式让探针针尖更锋利、更耐用,无需为频繁更换探针而耗费大量的时间和金钱。

Park NX20拥有业界便捷的设计和自动界面,让你在使用时无需花费大量的时间和精力,也不用为此而时时不停的指导初学者。借助这一系列特点,您可以更加专注于解决更为重大的问题,并为客户提供及时且富有洞察力的失效分析报告。

XY扫描仪包括对称的二维弯曲结构和高力量压电堆叠,提供高度正交运动以及微小的平面外运动,同时具备高响应性,非常适合在纳米尺度下进行精准样品扫描。

标准的Z扫描仪由高力量压电堆叠驱动,并由弯曲结构引导,具有超过9 kHz(通常为10.5 kHz)的高谐振频率,以及超过48 mm/sec的Z伺服速度,能够提供精准的反馈。可选的长扫描范围Z扫描仪可以将Z扫描范围从15µm扩展至30µm。

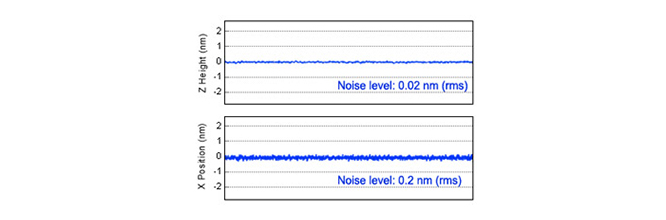

行业前沿的低噪声Z探测器替代了施加的Z电压作为形貌信号。此外,低噪声的XY闭环扫描精细化了前后扫描间隙,其大小不超过扫描范围的0.15%。

所有电动台上都配备了编码器,提高了样品定位的重复性。编码的XY台以1 µm分辨率移动,具有2 µm的重复性,编码的Z台以0.1 μm分辨率移动,具有1 μm的重复性。

使用电动样品台,Step-and-Scan 可以实现用户可编程的多区域成像。此自动化功能通过减少重复成像过程中用户的协助来提高生产力。

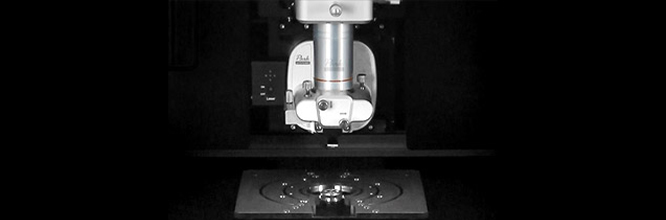

个性化的头部设计允许从侧面开放式接触样品和探针。可放置在样品台上的样品尺寸取决于所选的 XY 样品台的行程范围,直径可达200 mm X 200 mm 。

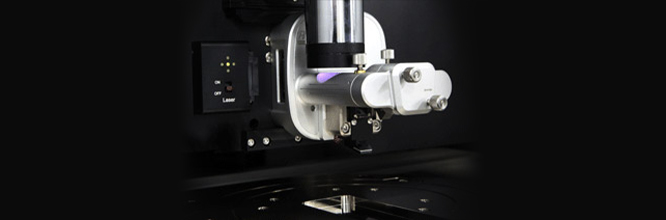

原子力显微镜 (AFM) 扫描头沿燕尾轨道快速滑入到位,自动锁定并精准连接到控制电子设备。超发光二极管 (SLD) 提供反射表面的精准成像,并实现精准的皮牛顿力-距离测量,而不干扰可见光谱实验。

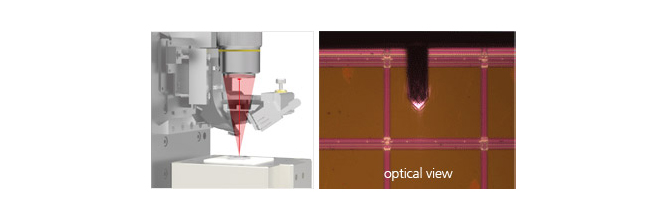

定制设计的物镜,具有51 mm 的工作距离和0.21 NA,提供1.0 µm的分辨率和清晰的同轴光学视图。自上而下的直接视图使目标区域的导航变得简易。EL20x 物镜具有20 mm 的工作距离、0.42 NA 和0.7 µm 的分辨率,以增强视野清晰度。更大的 CCD 传感器和软件控制的 LED 光确保了广泛的视野和充足的照明,以精准观察样品。

通过简单地将选项模块插入扩展插槽,可以启用 SPM 模式。NX 系列 AFM 的模块化设计允许其产品线中的选项兼容。

Z stage和聚焦台在保持用户视野清晰的同时,使悬臂与样品表面接触。而且由于聚焦台是电动和软件控制的,它具备透明样品和液体池应用所需的精度。

NX 系列 AFM 采用统一的 NX 电子控制器,24 位高速数字单元提高了 Park 的真正非接触模式的准确性和速度。其低噪声和快速处理非常适合纳米级成像和精准的电学测量,同时嵌入的数字信号处理增强了有效研究的功能性和价值。